Based on the spirit of respect for human beings and safety above all else, we will strive to ensure a completely accident-free workplace.

In addition, through the following initiatives, we have established safety standards that go beyond compliance.

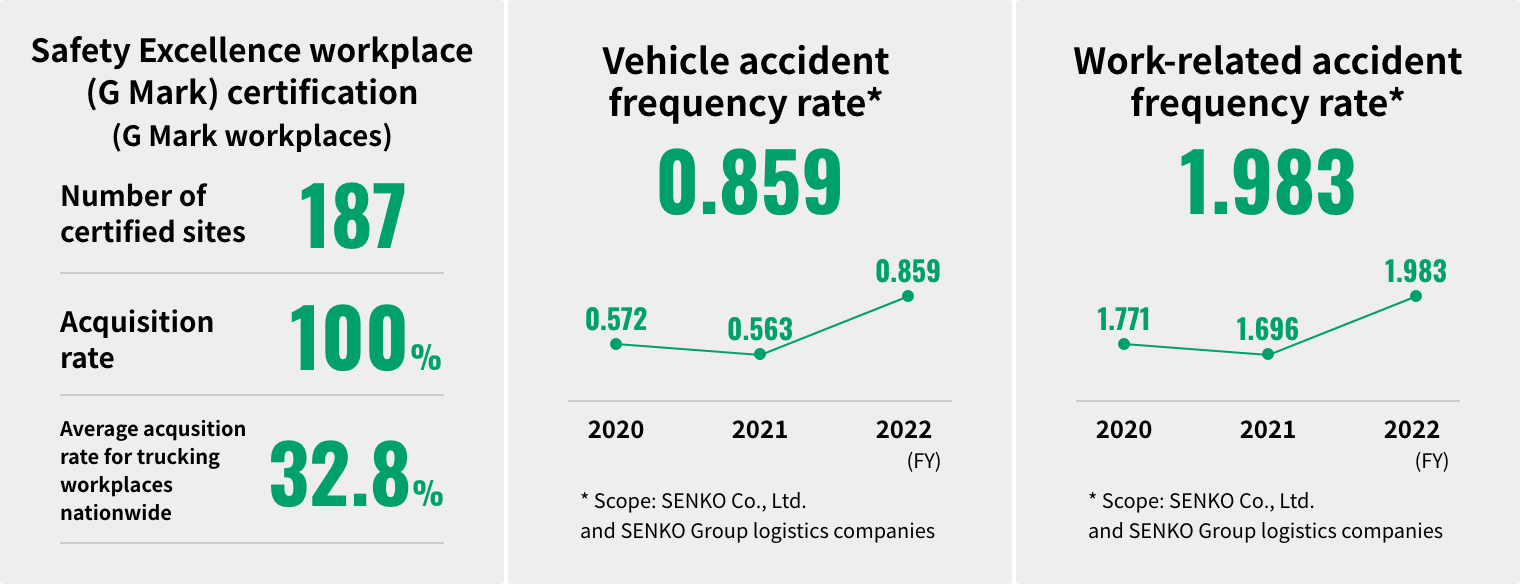

Based on the Safety and Health Management Regulations, we go through the PDCA cycle for annual targets, implementation and checking of measures, and improvements, and conduct internal audits (safety performance evaluations) of the level by field. We have established a reliable foundation of safety by utilizing a system that makes the results visible.

In warehouses, stored products create blind spots, and there is a lurking danger of collisions between people and forklifts. In response, we have introduced arch lights that light up to provide notification of the presence of a forklift. This prevents collisions even in warehouses with lots of noise and blind spots.

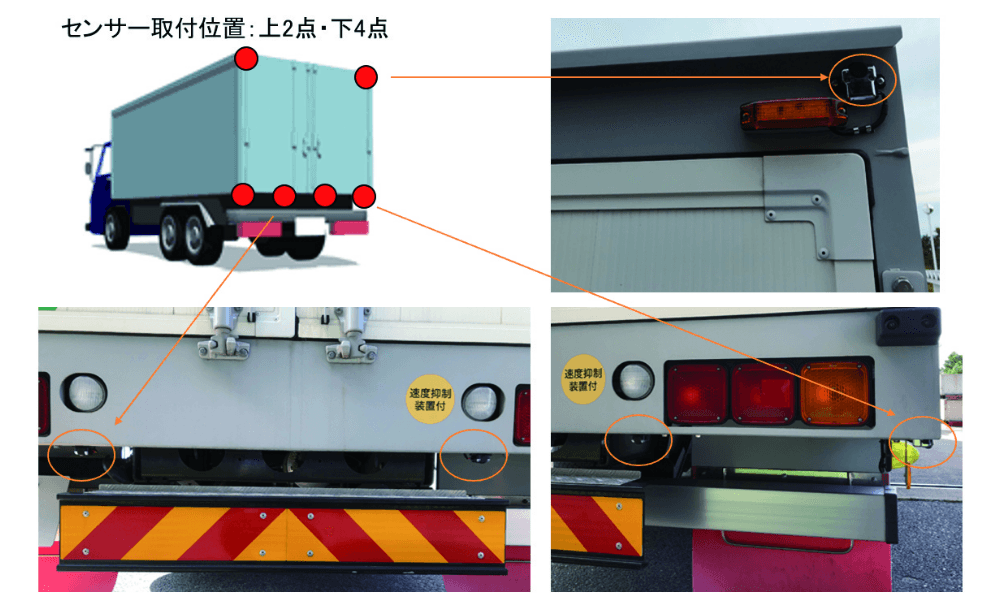

Truck accidents are most likely to occur when reversing. As a safety measure, Senko has installed truck sonar (rear proximity alarm devices) that prevents collisions by providing notification of rear obstacles.

We have introduced a trainer system to equalize the skill level of the field workers who contribute to the quality of logistics. Drivers and forklift operators who have received training at our in-house training facility, Crefeel Koto, become trainers and spread what they have learned to branch offices and sales offices in each region. This system has led to a reduction in the accident rate for drivers, and has received great praise from customers.

Since 2006, we have held Senko Group skill contests, with the goal of improving the skills of drivers and operators. We hold truck and forklift driving competitions where employees from all over the country and overseas compete in the logistics skills that provide safety and security to customers.

Based on the spirit of respect for human beings and safety above all else, Senko strives to have a completely accident-free workplace. In addition, in order to reliably protect and deliver our products in all conditions, we will maintain a safe working environment and continue to carry out safety activities that use advanced technology and skills to involve the entire group.