What management model should logistics companies adopt for a sustainable society?

Efforts by companies to achieve both economic growth and environmental conservation can be considered an essential foundation for creating a sustainable society. Especially now, it is necessary to reduce greenhouse gas emissions in order to curb climate change. Taking this global movement as an opportunity for economic growth, efforts to combine reduction of CO2 emissions with improvement of industrial competitiveness (Green Transformation, or GX) are attracting attention. Senko also sees the challenge of decarbonizing customers' entire supply chains as its responsibility as a logistics company, but also as a business opportunity. We are actively pursuing initiatives such as proposing efficient transportation methods with numerical targets set and introducing solar power generation that does not generate greenhouse gases.

Senko Group major numerical targets

(FY2022-2026 Medium-term Management Plan)

10%reduction in CO2 emissions intensity (land transport business) compared to FY2020

Main Initiatives:

Progress in in-house environmental measures and modal shift

The following are the environmental measures that Senko is focusing on, such as modal shifts and our in-house environmental measures.

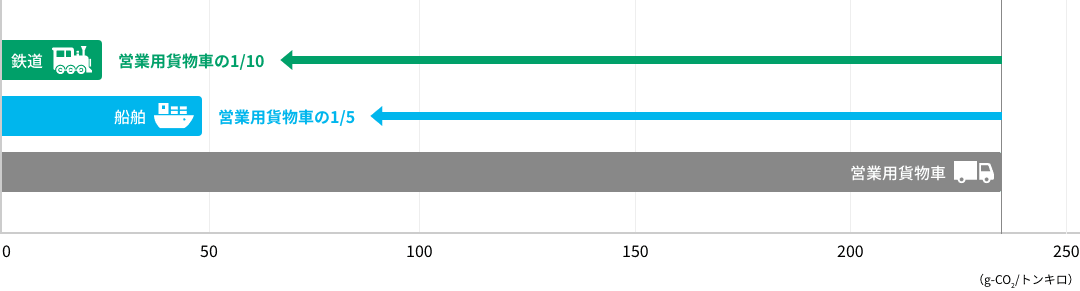

Senko is moving forward with a modal shift to the overlapping use of trucks, railroads, and ships in long-distance trunk transport with one-way distances exceeding 500 km. In addition to decarbonization, modal shifts can also help maintain stable transport by reducing long-distance transport and promoting work style reforms for drivers. In addition, we are promoting marine transport as a transport mode that is resistant to risks such as disruption of roads and railroads by natural disasters.

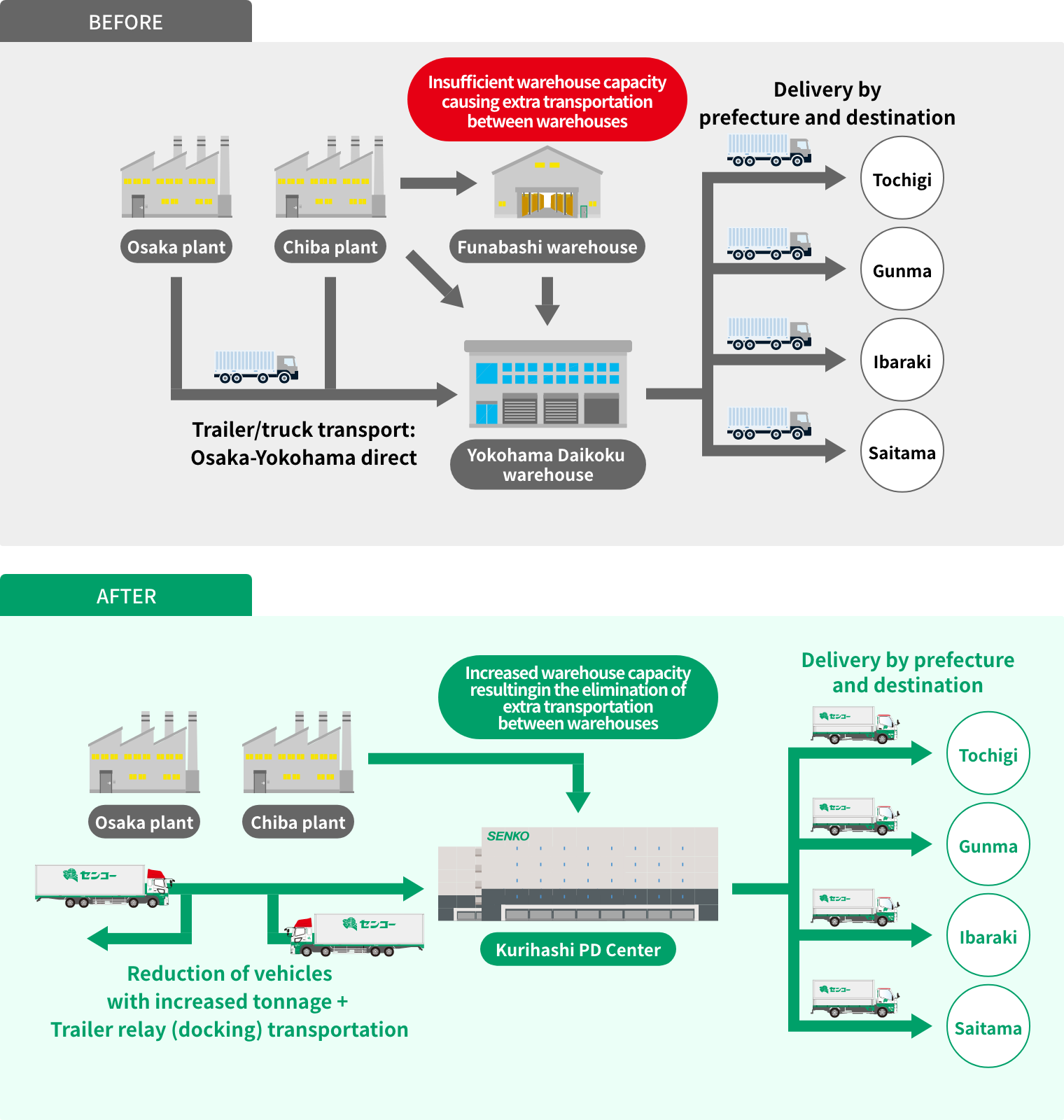

Shortening truck driving distances by relocating logistics sites/Reducing driver working hours by introducing transportation relay points

In the past, deliveries from Fuji Oil Co., Ltd.'s Chiba plant to the Kanto area (Saitama, Ibaraki, Tochigi, Gunma, etc.) were temporarily stored in a warehouse near the factory or transferred to another warehouse, but by moving them to the Senko warehouse in Saitama Prefecture, we were able to reduce CO2 emissions by shortening the truck travel distance. In addition, we were able to switch transportation from Osaka Prefecture to the Kanto region to relay transportation using trailers, which was highly evaluated as reducing CO2 and the burden on drivers.

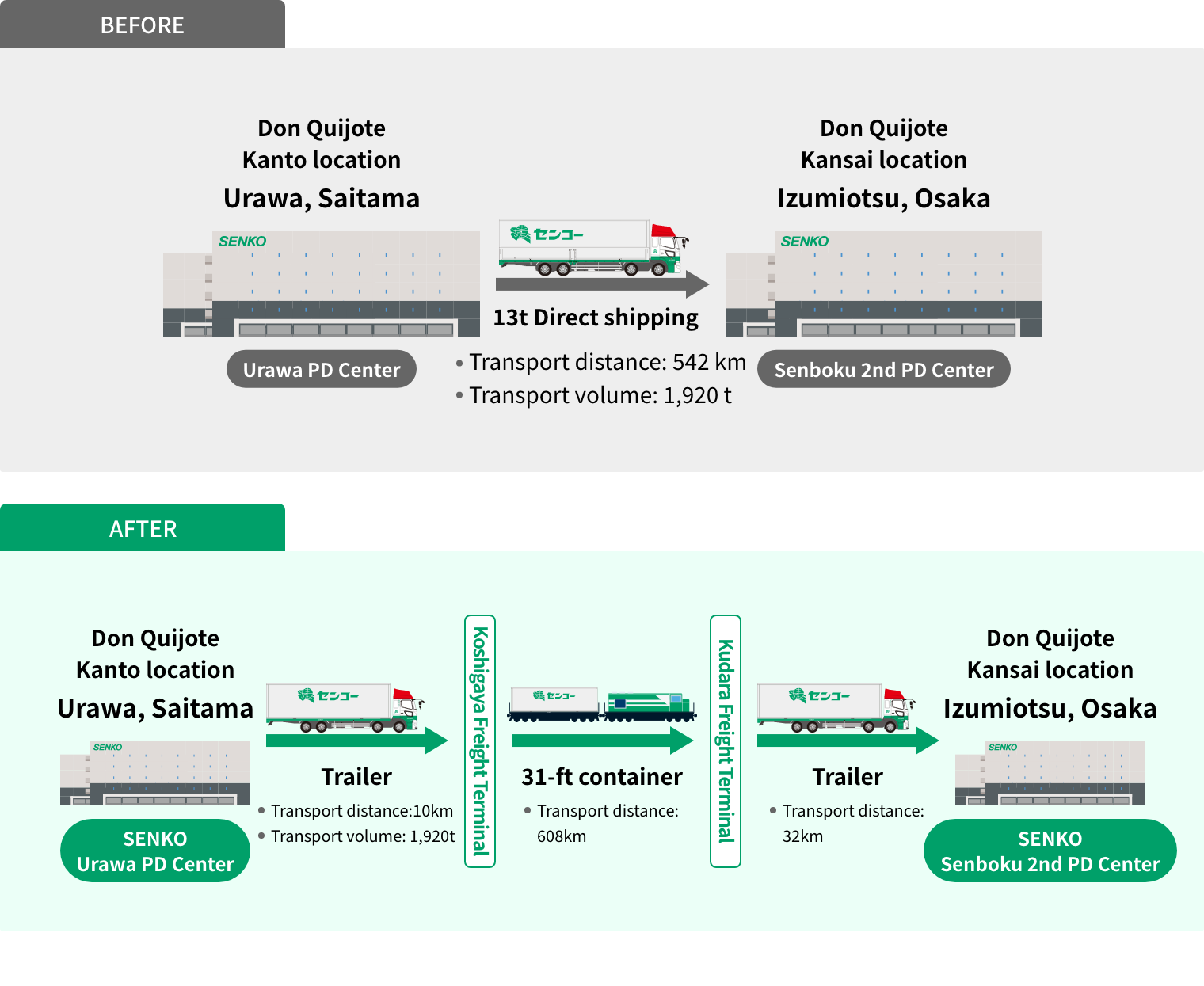

Modal shift using rail routes for mainlines between eastern and western regions

Senko and Saitama Minami Senko were recognized for their successful reduction of CO2 emissions and the burden on drivers by converting Pan Pacific International Holdings Corporation's transportation of sundries from Saitama Prefecture to Osaka Prefecture from truck to rail transport.

※Don Quijote is a group company of Pan Pacific International Holdings.

We received a total of three awards: One in the Improvement category and two in the Efficient Utilization category. In the Improvement category, Senko achieved the commendation standard of a modal shift transportation ratio of over 40% using rail and marine transport among the mainline transportation volume between all locations in FY2021. Furthermore, the ratio of modal-shifted transportation increased from 74.9% in FY2020 to 76.1% in FY2021, a higher amount of progress in the modal shift. The first project in the Effective Utilization category is for Runtec's contribution to the reduction of CO2 emissions by switching from less-than-container-load truck transport to rail transport using 31-foot containers for the transportation of consolidated frozen shipments from Miyagi Prefecture to Hyogo Prefecture. When switching to rail transport, Runtec achieved a modal shift without changing the shipping volume by negotiating with each shipper to bring forward the shipping time and shortening the loading time through innovations in on-site work. In the second project, Senko switched from truck transport to rail transport using 31-foot containers for the transportation of inventory of daily necessities from Saitama Prefecture to Osaka Prefecture. When switching to rail transport, we coordinated loading and unloading times with each party according to train departure and arrival times. In addition, since the cargo transported is bulk-loaded and bulk-distributed, and the container loading weight (8 tons) and the truck loading weight (13 tons) are different, we have achieved reliable transport by working hard to improve efficiency every day through innovations in vehicle allocation and adjustments to the volume of cargo.

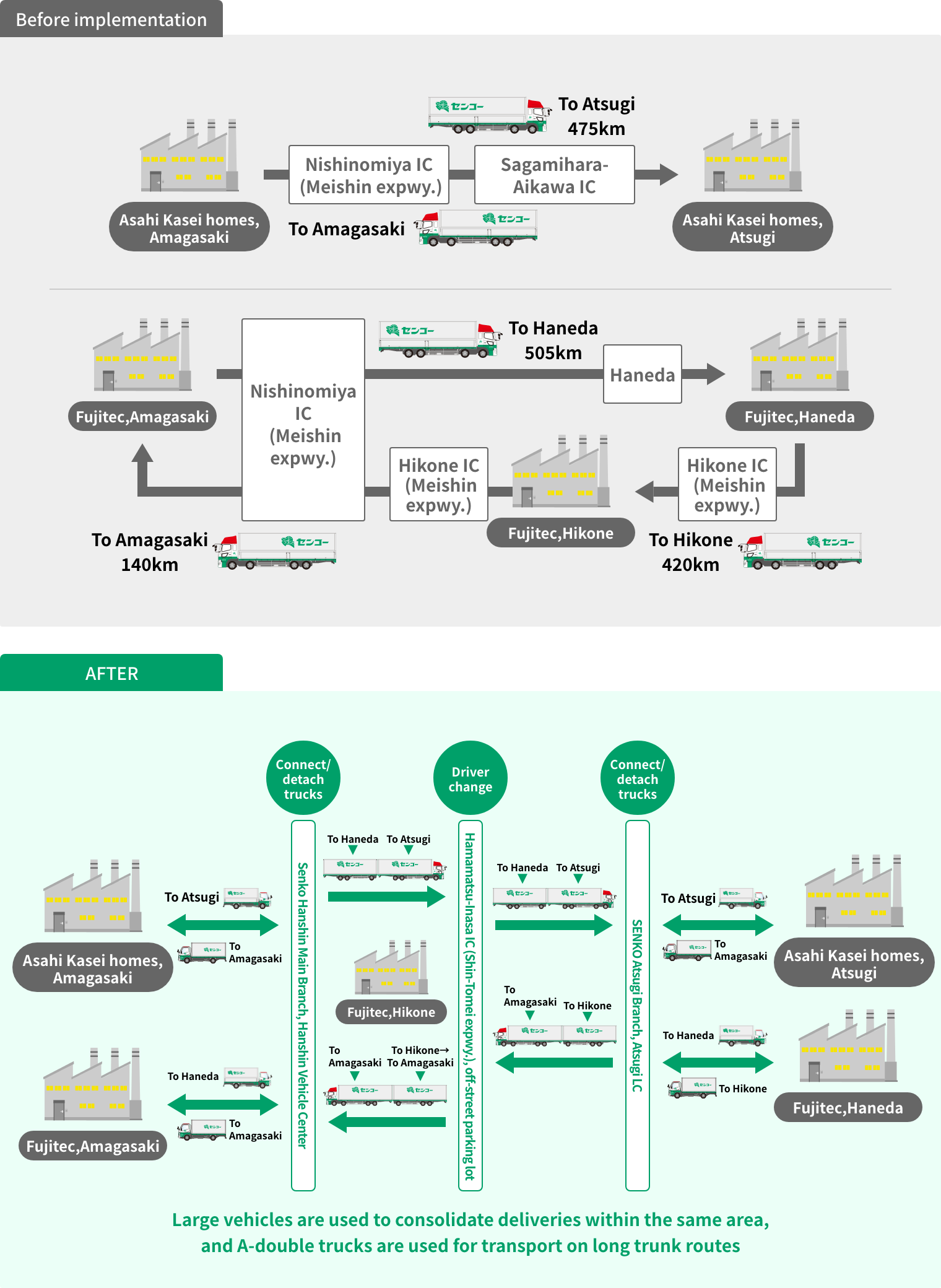

Introduction of A-double trucks

In order to reduce greenhouse gas emissions in the customers' supply chains, Senko is making efforts on the hardware side of transportation related to both the upstream part of logistics (procurement of raw materials) and the downstream part (supply of products to the market). One aspect of this is the introduction of 25 m-long A-double trucks for long-distance transport. This was awarded the 2022 Excellent Logistics Partnership Commendation in the Logistics Structural Reform Award category.

As part of the logistics bus service menu, in February 2021 we started operating an A-double truck that allows one driver to transport two large trucks' worth of luggage for long-distance transport. Two large-sized trucks pick up packages separately, and the two trucks are connected and departed from Senko's location as an A-double truck. During the long-distance highway segment, it is transported by a single driver and during its journey the driver is replaced at the A-double truck docking station, it is driven by another single person up to the detachment point, where it is divided into two vehicles, a large truck and a semi-trailer, by what is called the dolly method* and they head to each destination at the same time. This contributes to double reduction of driver hours and CO2 emissions.

* Dolly method: Connecting and detaching from the trailer using a dolly (coupling device)

Learn more about logistics buses

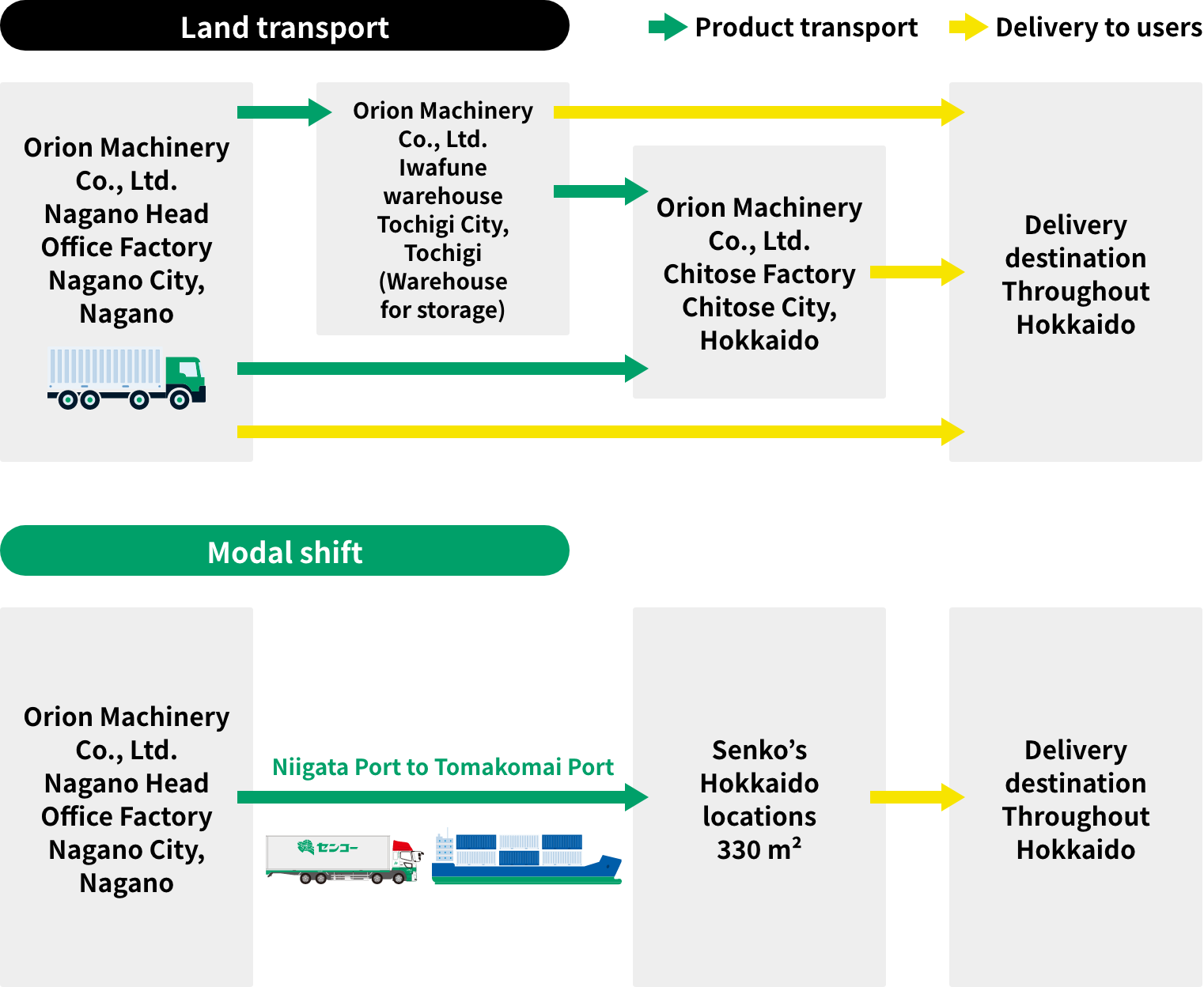

Progress in the use of ferries for modal shift of long-distance transport

Orion Machinery Co., Ltd., Marinex Co., Ltd. (a logistics subsidiary of Shin Nihonkai Ferry Co., Ltd.), and Senko have been certified as Eco-Ship Modal Shift Business Operators in 2021 for progress in the modal shift of the long-distance transport of portable heaters and dryers manufactured by Orion Machinery toward the use of ferries.

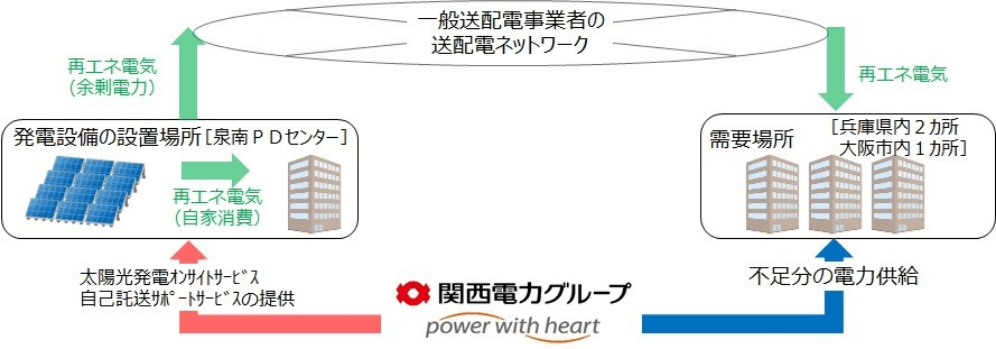

As a logistics company, in addition to the initiatives mentioned above, Senko is actively promoting the introduction of eco-friendly vehicles and solar power generation systems at large logistics facilities as measures to reduce CO2 emissions that cause global warming. At the Senko Sennan PD Center, a large-scale logistics facility completed in March 2022, the solar power self-consumption PPA model has been introduced, and the power used by the center is self-generated by the solar panels (682.5 kW) installed on the entire rooftop. Also, self-consignment of surplus electricity between Senko Group companies was started. In collaboration with the Kansai Electric Power Co., Inc., we started power generation and self-consignment on April 1st. The self-consignment destinations are Senko's two logistics facilities in Hyogo Prefecture and one commercial facility operated by group company Terauchi in Osaka City. This was the first initiative in Japan to carry out self-consignment to three locations across multiple companies within the group.

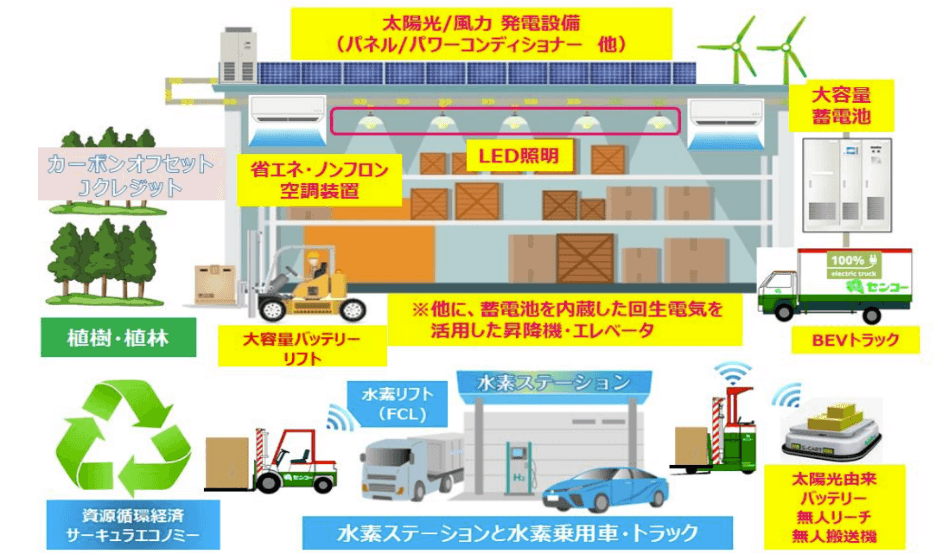

The future of logistics that Senko is working towards is zero-environmental-impact logistics, with the goal of achieving carbon neutrality by 2050. This is an overview of the zero-CO2 logistics center that we are working towards.

Overview of zero-CO2 logistics center

Uses renewable energy to eliminate CO2 emissions at logistics centers. Introduces next-generation vehicles and utilizes generated renewable energy. With these and other initiatives, Senko is making steady progress toward achieving a sustainable society. We hope you look forward to Senko's creation of a new future.

Details of the Senko Group's environmental initiatives are listed below.

Please take a look at them.