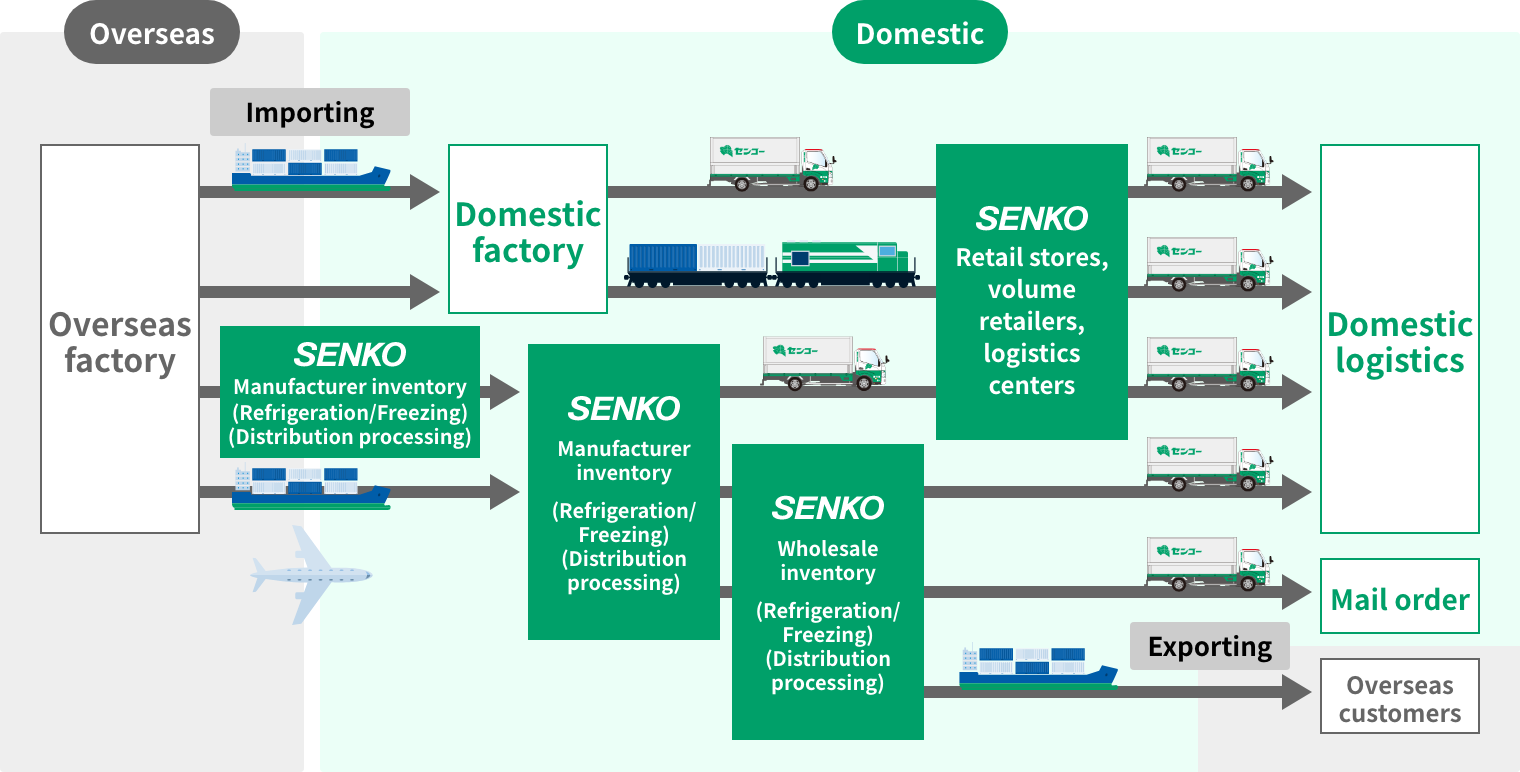

Total support for our customers’ food logistics strategies, from overseas procurement of raw materials to domestic delivery of products to end-users

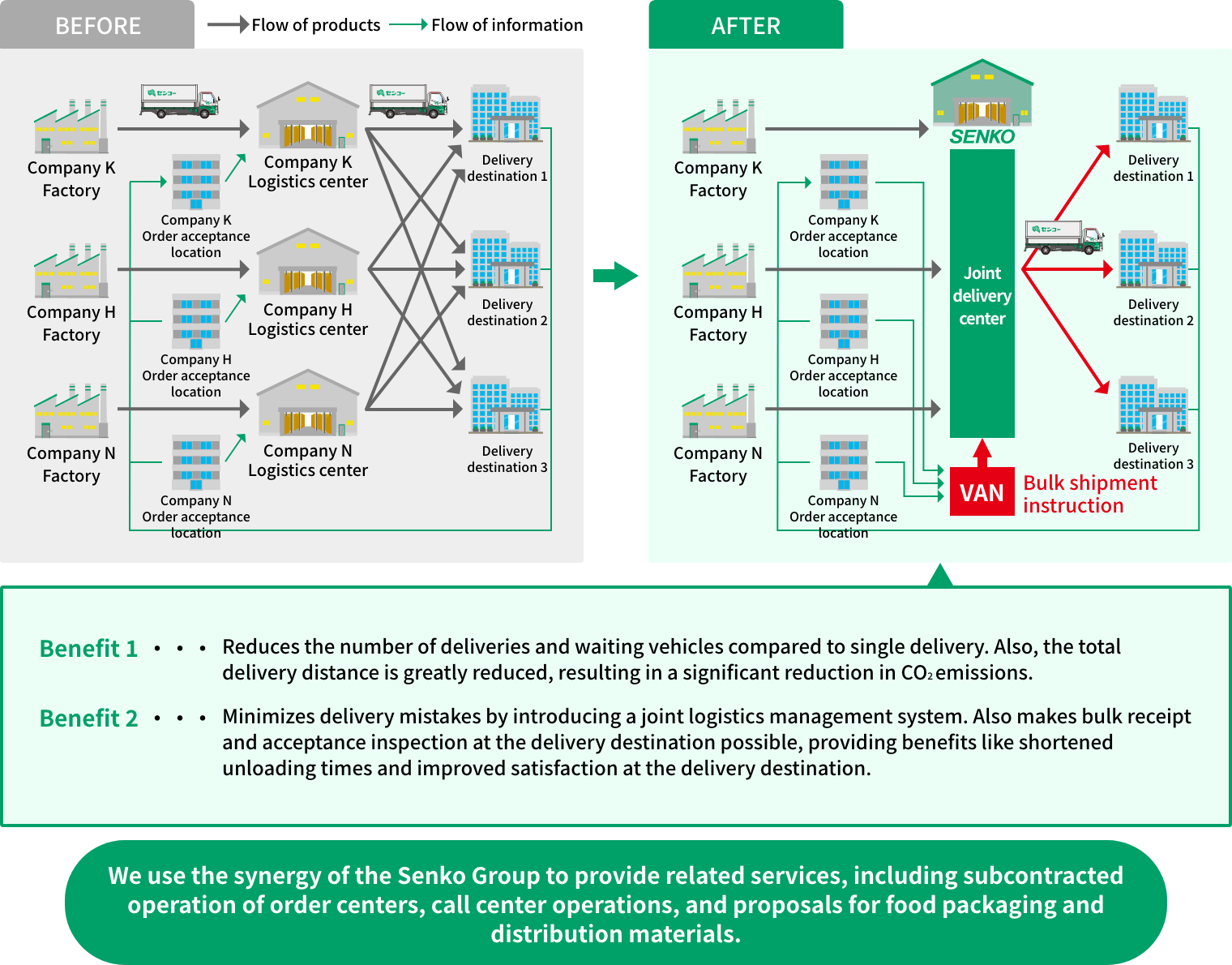

The food distribution industry requires strict control of temperature and sanitation while demanding short lead times and strict observance of delivery dates. Providing speed, safety, and security is indispensable. In addition, customer needs are becoming more diverse and sophisticated, such as frequent delivery of small lots that are unique to food distribution, maintaining freshness, distribution processing, and dealing with fluctuations in distribution. Senko has accumulated unique know-how while handling many types of logistics, and gives all customers services optimized for them.

<Main types of businesses we handle>

Food manufacturers, food wholesalers, supermarkets, restaurants, retail specialty stores, mail order, etc.

We can provide support to you through every transportation channel: by road, railroad, sea, or air.

We use systems that centrally manage the flow of information and products to add efficiency to food logistics. We also use wireless handheld terminals for all operations and have established simple workflows that anyone can handle.

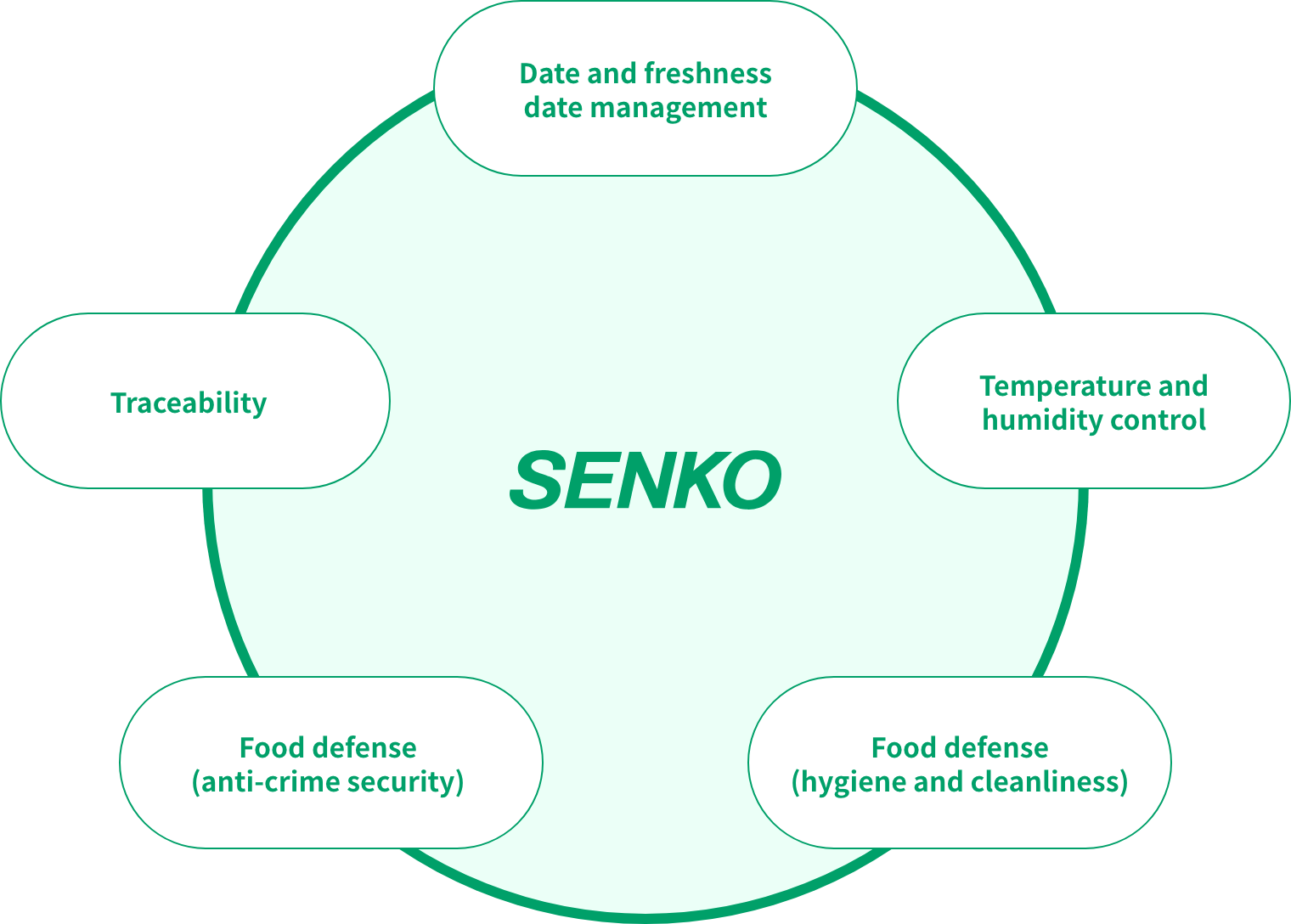

Almost all food products have expiration or freshness dates. The food industry follows what is called the "one in three" rule. Senko uses a food distribution system to check the expiration date for each product when it arrives and when it ships, providing freshness management that prevents dates from being rolled back.

All food products, especially perishables, must be stored and delivered under the best temperature and humidity control for them. Senko's food logistics provides a cold chain service that controls optimal temperature and humidity from the production plant to the end user.

What is a cold chain (low-temperature distribution system)?

A system that consistently distributes products from producers to consumers while maintaining low temperatures through freezing and refrigeration. It can be used for products like foods, pharmaceuticals, chemicals, electronic components, and blood. Runtec is the Senko Group's main provider for this service.

In order to prevent unintentional contamination of food with foreign substances, hygiene management is carried out in the logistics center according to the type of work.

* This includes installation of air showers at the entrance of distribution processing work sites, wearing special uniforms and hats, observing hand-washing rules, controlling insects and rats, and conducting employee health checks before work.

In order to prevent intentional contamination of food with foreign substances, we take responsibility as a company for security measures to prevent crime within our logistics centers.

* This includes installation of surveillance cameras, management of vehicle entry and exit at gates, management of employee entry and exit using IC cards, and installation of perimeter fences.

Today's demand for food safety and security makes it necessary to establish product traceability at the distribution stage. Senko's food logistics uses a system to manage product lots, making it possible to track information about individual products (when, from which warehouse, to which delivery destination, and which lot) when needed.

We will propose the right service for the problems and issues that we are frequently asked about.

Contact us for inquiries about Senko’s products and services

Logistics Sales Division

+81-3-6862-7154