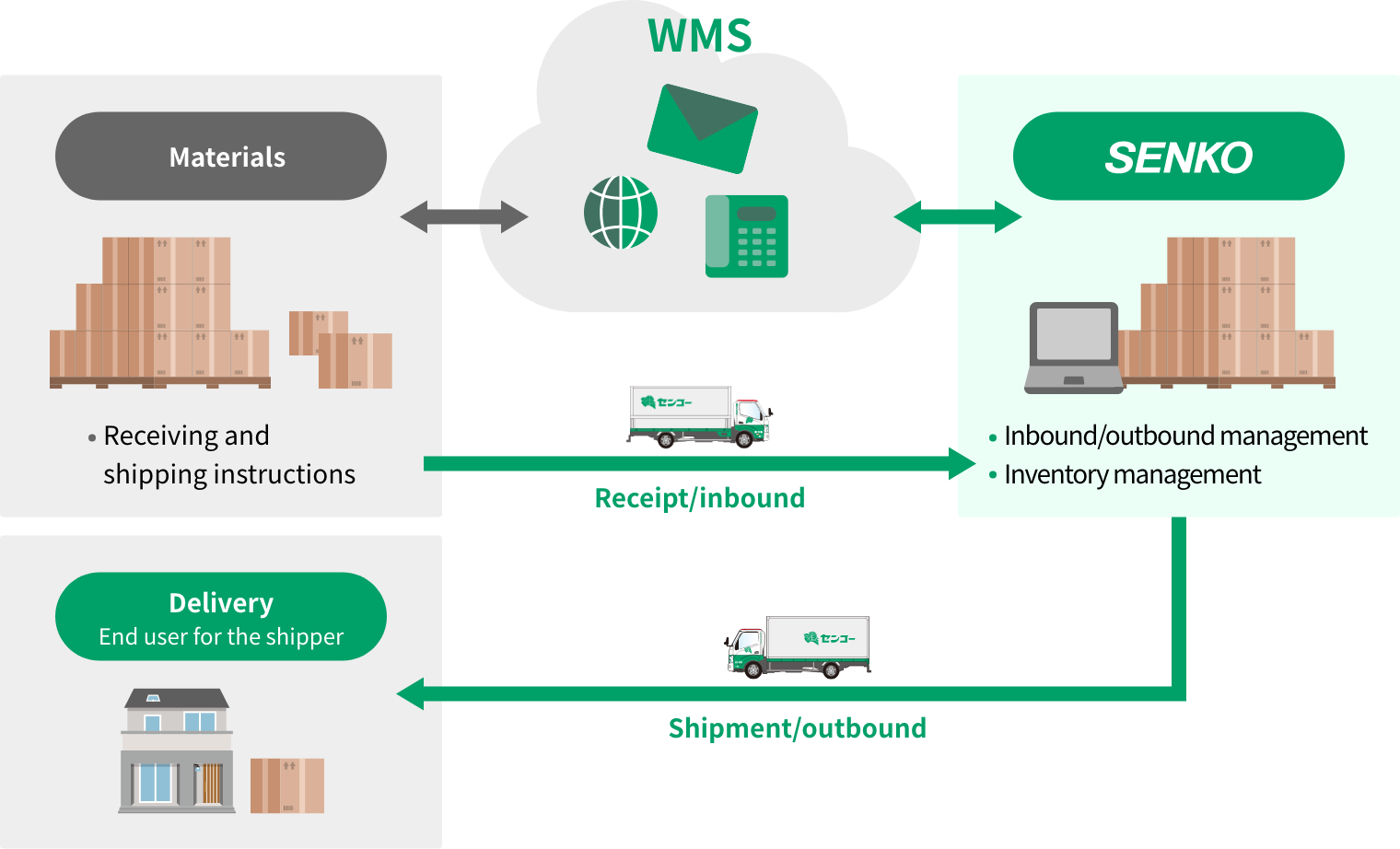

Overview of WMS

Managing the inbound/outbound and inventory information of entrusted goods with WMS enables you to check all kinds of information at any time.

We provide support to and meet on-site needs for warehouses of all types and scales in industries including housing materials, petrochemicals, resins, and mass-market products.

Advantages of WMS

- Provides systems that match the type of shipper and the product characteristics

- Optimizes inventory management for product characteristics (first-in, first-out inventory management for free and fixed locations)

- Strictly manages product freshness and expiry dates

- Linkable with material handling equipment

- Achieves work efficiency and quality improvement by linking with mobile terminals

- Meets the needs of all kinds of locations, from private warehouses and small warehouses to large-scale warehouses of 100,000 square meters

Functions of WMS

Inventory management

- Inventory lookup

- Location management

- Inventory status management

- Stocktaking functions

Outbound management

- Outbound inspection functions

- Reservation priority functions

- Packaging calculation

- Various ledgers

Stocktaking management

- Inbound inspection functions

- Inbound status lookup

- Various ledgers

Linkage with EDI

- Zengin TCP/IP

- Distribution BMS

- HULFT

Linkage with TMS

- Real-time invoice linkage

- Automatic reflection of dispatch results on the WMS

Other

- Linkage with material handling equipment

- Linkage with voice terminals

- Linkage with OCR terminals

Examples of Use

- Warehouse management for housing manufacturers

- Warehouse management for resin manufacturers

- Warehouse management for petrochemical manufacturers

- Warehouse management for volume sales businesses (retail, major supermarkets, clothing)

WMS is used by a wide range of businesses, and have a proven track record overseas as well.

Cloud Transportation Management Systems

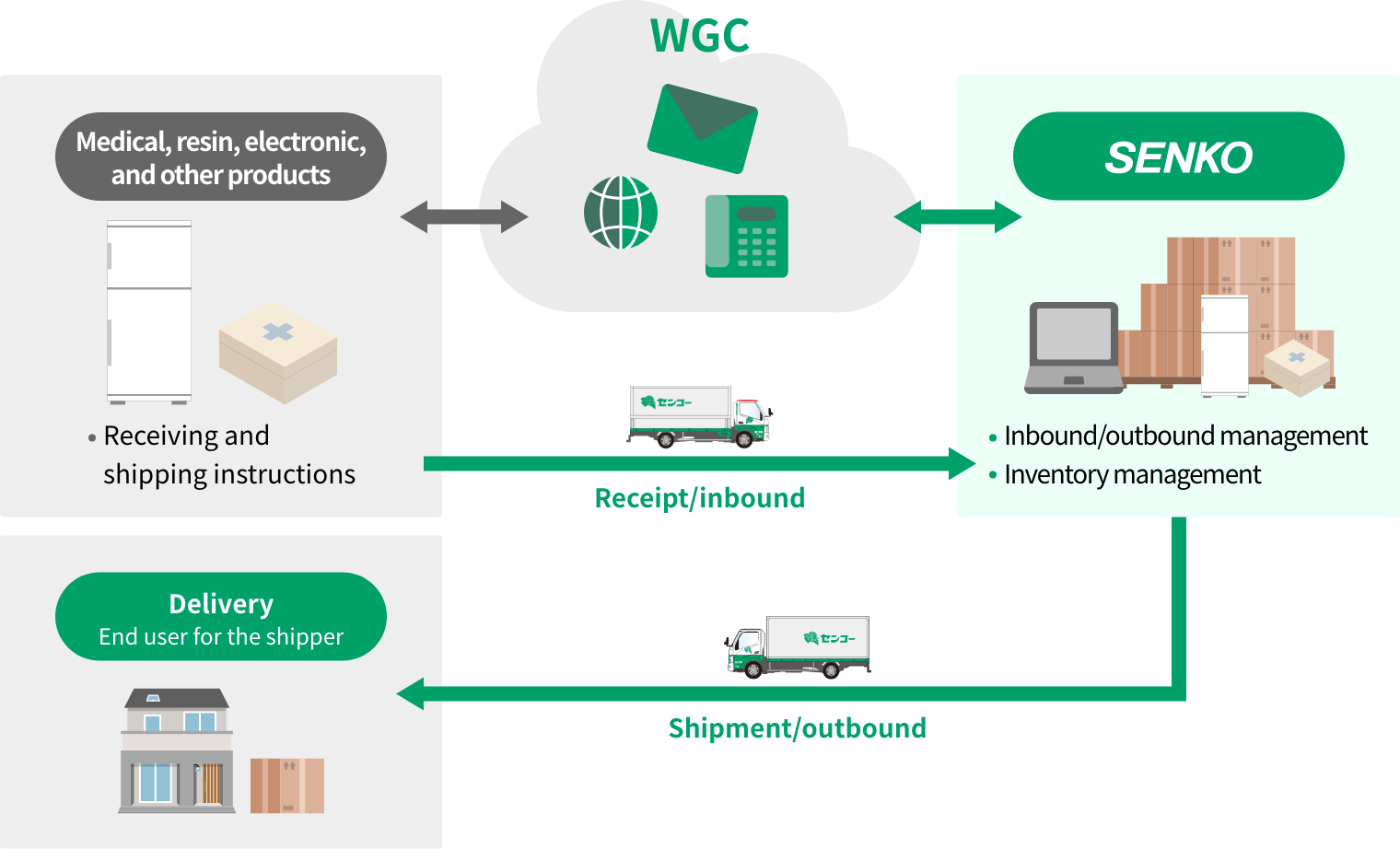

Warehouse Generic Cloud (WGC)

Overview of WGC

This is a cloud warehouse management system that meets all of the needs of customers who are looking for inventory optimization, visualization, management of warehouse work, and improvements to warehousing duties--from arrival to the warehouse to shipment.

It responds to all kinds of warehouses and on-site needs in the resins, homebuilding, medical, and other industries, from private warehouses and small warehouses to large-scale warehouses of 100,000 square meters.

It also improves work efficiency and quality by linking with mobile terminals, and seamlessly integrates with TMS and other external systems.

Advantages of WGC

- A general-purpose warehouse management system that can handle any type of business

- The necessary functions can be selected by master tuning

- New warehouse locations and customers can be introduced quickly and at low cost

- Improved work efficiency through voice picking and linkage with OCR equipment

Functions of WGC

- Support for common types of inventory management (lot management, expiration date management, serial management)

- Incoming and outgoing warehouse management with handheld terminals and tablets

- Various types of picking (total picking, single picking)

- Progress management of warehouse work

- Support for various methods of warehousing fee calculation

- Multi-language support (English and Chinese)

WGC case studies

Company S: Solar battery manufacturer

- Products

- CIS solar battery modules

- Scale

- 10,000 m2 used

- Business details

- Receiving, storage, shipment, inventory, public/industrial and residential (individual) delivery

Company D: Manufacturer of residential building materials

- Products

- Fiberboard (wood, mineral wool), VSF (Dailite), MDF, special plywood, inorganic board, housing equipment

- Scale

- 7,000 m2 used

- Business details

- Receiving, storage, shipment, inventory

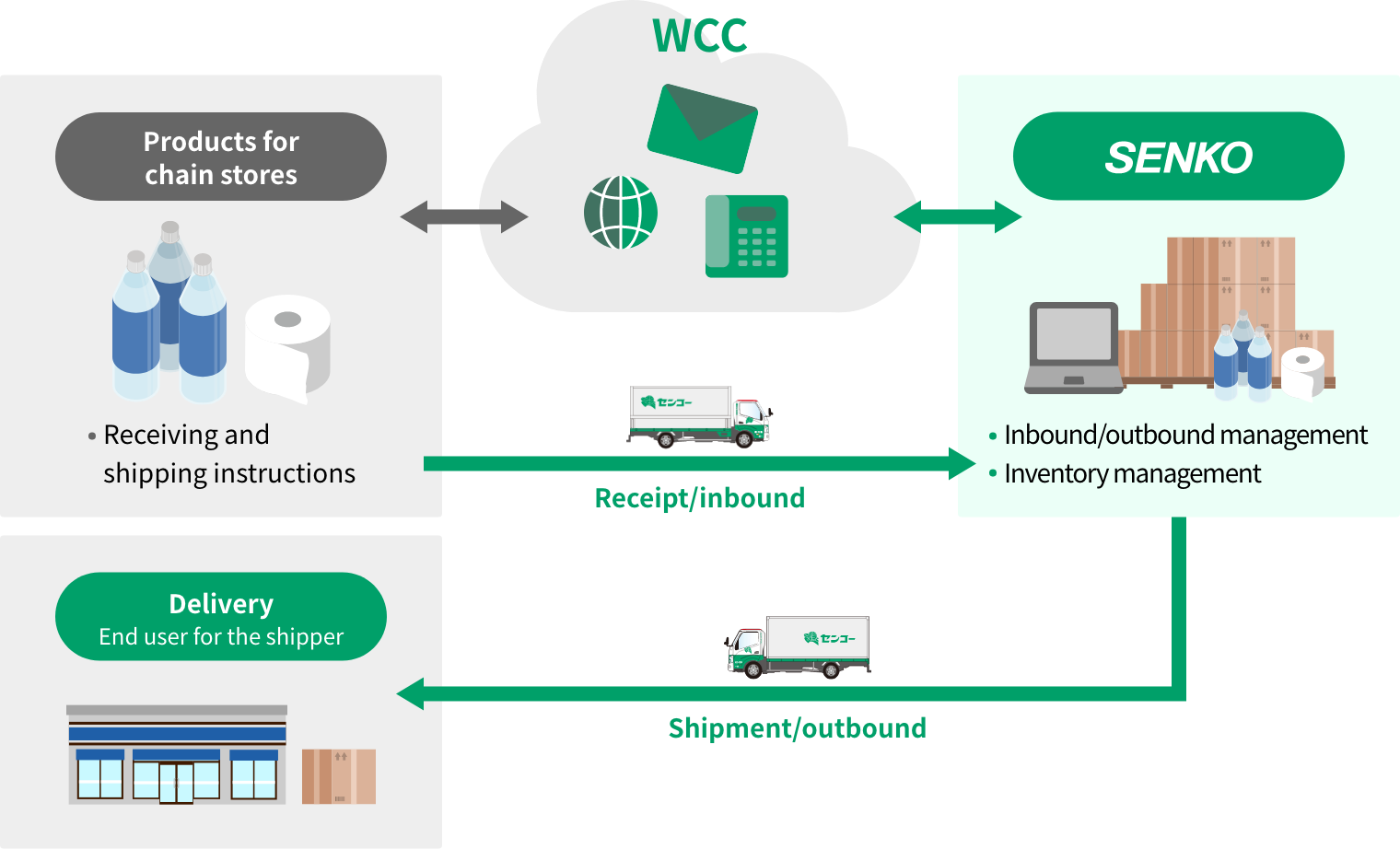

Warehouse Chainstore Cloud (WCC)

Overview of WCC

This is Senko's unique standard warehouse management system that can handle the many operations of chain store logistics, such as product management, expiration date confirmation, and lot management using JAN codes.

It reduces shipping costs through paperless inspections and makes immediate rollout possible because there is no data exchange via the web ordering system.

Advantages of WCC

- Improves work efficiency and quality by using wireless handheld terminals and portable printers for receipt/shipment and inventory management

- Can compress storage locations through free location management

- Improves work efficiency and quality through barcode inspections

- Reduces operation costs through paperless inspections

- Provides a web-based system for external disclosure to customers and related parties

Functions of WCC

- Product management functions using JAN/product codes

- A wide variety of shipment inspection functions

- Web-based sales order management functions

- Mail order logistics functions

- Progress management functions for quality inspection work

WCC case studies

Company D: Pharmaceutical manufacturer (B to B)

- Products

- Processed foods

- Scale

- 700 m2 used

- Business details

- Destination: Company-owned stores

Company A: Cosmetics manufacturer (B to B, B to C)

- Products

- Cosmetics

- Scale

- 3,000 m2 used

- Business details

- Receiving, storage, shipment, inventory, customer returns, disposal, and quality inspection for catalog and online mail-order sales to individuals

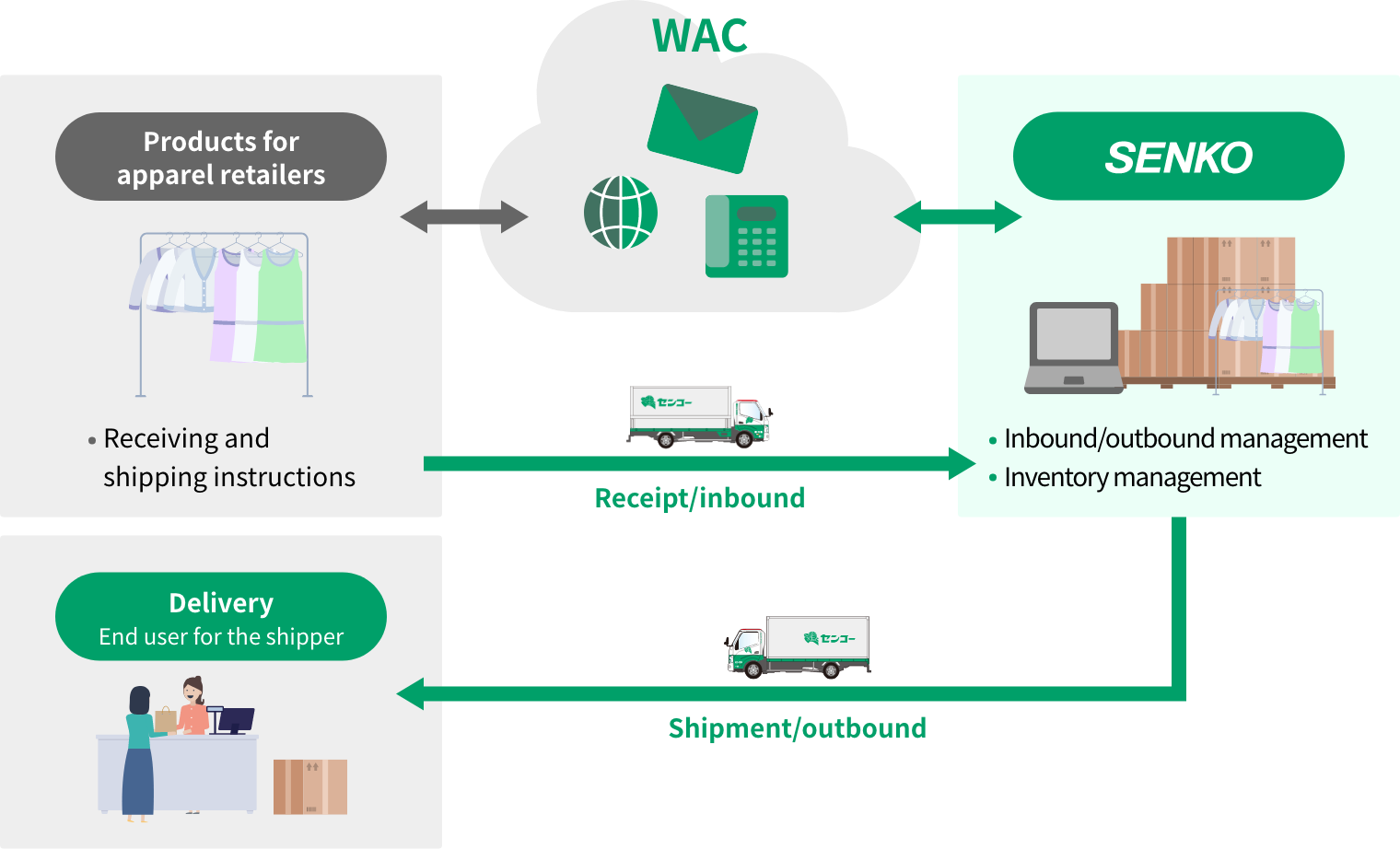

Warehouse Apparel Cloud (WAC)

Overview of WAC

This is Senko's unique apparel warehouse management system that can handle the many operations of apparel logistics.

Whether for department store delivery or personal delivery, it improves productivity based on the operation of apparel logistics and the work productivity figures for each task and individual.

Advantages of WAC

- Improves work efficiency and quality by using wireless handheld terminals and portable printers for receipt/shipment and inventory management

- Automatically issues price tags and invoices from WMS

- Can compress storage locations through free location management

- Can output necessary KPI data for customer submissions and in-house management materials

- Provides a web-based system for external disclosure to customers, related parties, and clients

Functions of WAC

- Functions for product management by product number, color, shape, and size

- Receipt/shipment, return, distribution processing (repair, pricing, quality inspection), and stocktaking functions

- EDI functions for department stores

- Mail order logistics functions

- Progress management functions for quality inspection work

- Functions for coordination with delivery agencies

WAC case studies

Company S: Apparel manufacturer (B to B)

- Products

- Apparel, shoes, bags, and accessories *Garment-on-hanger, flat pack, and miscellaneous goods

- Scale

- 70,000 m2 used

- Business details

- Destination: Department stores, company-owned stores, and outlets

Distribution processing: Price tag issuance, price tag attachment, reuse of returned goods, physical shipment, etc.

Company O: Apparel manufacturer (B to B, B to C)

- Products

- Apparel, shoes, bags, and accessories *Garment-on-hanger, flat pack, and miscellaneous goods

- Scale

- 30,000 m2 used

Number of workers: 150

- Business details

- Receiving, storage, shipment, inventory, customer returns, manufacturer returns, disposal, quality inspection, and barcode issuance and attachment for catalog and online mail-order sales to individuals

- Features

- Supports verification of catalog specifications, special paper packaging, name personalization, insertion of message cards, and hemming for slacks, etc.

SENKO INFORMATION SYSTEM Co.,Ltd.